Instructional Design Models: A Comprehensive Overview

Instructional designers typically employ models like ADDIE, Gagné’s Nine Events, and Kirkpatrick’s Evaluation, often adapting them to specific contexts for effective learning experiences.

Instructional design models serve as blueprints for creating effective and engaging learning experiences. These frameworks guide instructional designers through a systematic process, ensuring that learning objectives are met and that instruction is aligned with established learning theories. Designers frequently utilize models such as ADDIE – encompassing analysis, design, development, implementation, and evaluation – as a foundational structure.

Other prominent models include Gagné’s Nine Events of Instruction, which outlines a sequence of events to facilitate learning, and Kirkpatrick’s Four Levels of Evaluation, used to assess the impact of training programs. The selection of a model often depends on the specific context, learning objectives, and target audience.

These models aren’t rigid prescriptions, but rather adaptable frameworks. Instructional designers often blend elements from different models to create a customized approach, ensuring optimal learning outcomes. Understanding these models is crucial for anyone involved in the creation of educational materials or training programs.

The Importance of Models in Instructional Design

Instructional design models are paramount because they provide a structured approach to a complex process. Without a model, creating effective learning experiences can be haphazard and inefficient. Models ensure consistency, allowing for repeatable and reliable results in training and education. They facilitate clear communication among stakeholders – designers, developers, and instructors – by establishing a common language and understanding.

Furthermore, models ground design decisions in established learning theories, such as behaviorism, cognitivism, and constructivism. This theoretical foundation increases the likelihood of successful learning outcomes. Models like ADDIE, while sometimes critiqued, offer a widely recognized and adaptable framework.

Employing a model also encourages systematic evaluation, allowing designers to identify areas for improvement and refine their approach. Ultimately, models enhance the quality, effectiveness, and impact of instructional materials.

Foundational Learning Theories Influencing Instructional Design

Instructional designers typically employ models rooted in learning theories – behaviorism, cognitive theory, and constructivism – to shape strategies and maximize learner engagement and knowledge retention.

Behaviorism and its Impact on Design

Behaviorism, a foundational learning theory, significantly impacts instructional design by emphasizing observable changes in behavior through stimulus-response interactions. Designers employing behaviorist principles focus on clearly defined objectives, breaking down complex skills into smaller, manageable steps.

This approach utilizes reinforcement – positive or negative – to encourage desired behaviors and discourage unwanted ones. Techniques like drills, practice, and immediate feedback are central to behaviorist-aligned instruction. Instructional models influenced by behaviorism often prioritize external motivators and structured learning environments.

While modern instructional design often integrates other theories, behaviorism’s legacy remains in techniques like programmed instruction and skill-and-drill exercises. It’s particularly effective for establishing foundational knowledge and procedural skills, though its limitations in fostering higher-order thinking are acknowledged. Designers balance behaviorist techniques with cognitive and constructivist approaches for holistic learning.

Cognitive Theory and Instructional Strategies

Cognitive theory shifts the focus from observable behaviors to internal mental processes – how learners acquire, process, and store information. Instructional designers leveraging this theory prioritize strategies that facilitate meaningful encoding, retrieval, and transfer of knowledge.

Key strategies include using advance organizers to provide context, chunking information into manageable units, and employing mnemonics to aid memory. Elaboration, encouraging learners to connect new information to existing knowledge, is also crucial.

Cognitive load theory informs design choices, aiming to minimize extraneous cognitive load and optimize germane load – the effort dedicated to deep processing. Instructional models influenced by cognitive theory emphasize active learning, problem-solving, and the development of mental schemas. Effective strategies also include providing opportunities for practice and feedback to strengthen neural pathways and improve retention.

Constructivism: Learner-Centered Approaches

Constructivism posits that learners actively construct their own understanding and knowledge of the world, rather than passively receiving information. Instructional designers embracing this theory prioritize learner-centered approaches, fostering environments where exploration, discovery, and collaboration thrive.

Strategies include problem-based learning, case studies, and simulations, encouraging learners to apply knowledge to authentic contexts. Scaffolding, providing temporary support structures, is vital to guide learners through challenging tasks within their Zone of Proximal Development.

Emphasis is placed on social interaction and knowledge sharing, recognizing that learning is a social process. Assessment shifts from measuring recall to evaluating the application and creation of knowledge. Constructivist models empower learners to take ownership of their learning journey, promoting deeper understanding and long-term retention through active participation and reflection.

Key Instructional Design Models

Instructional designers typically employ models such as ADDIE, Gagné’s Nine Events, and Kirkpatrick’s Four Levels, providing frameworks for systematic and effective learning interventions.

ADDIE Model: The Industry Standard

The ADDIE model—Analysis, Design, Development, Implementation, and Evaluation—stands as the cornerstone of instructional design, widely recognized and utilized across various sectors. It’s considered the archetype upon which many newer, specialized models are built. The initial Analysis phase involves a thorough understanding of the learners, their needs, and the learning environment.

Following analysis, the Design phase focuses on crafting learning objectives and outlining the instructional strategies. Development then brings these designs to life, creating content and materials. Implementation is the delivery of the instruction, and finally, Evaluation assesses the effectiveness of the entire process.

This iterative approach allows for continuous improvement. While sometimes criticized for its linearity, its adaptability and comprehensive nature make it a consistently valuable framework for instructional designers seeking a structured and proven methodology. It provides a solid foundation for creating impactful learning experiences.

Analysis Phase of ADDIE

The Analysis phase of the ADDIE model is foundational, demanding a deep dive into understanding the learning context. Instructional designers begin by identifying the instructional problem or opportunity, defining the target audience’s characteristics – their existing knowledge, skills, and attitudes. A crucial step involves pinpointing the learning goals and objectives; what should learners be able to do after the instruction?

This phase also necessitates a thorough needs assessment, examining the gap between the current state and the desired state. Constraints, such as budget, time, and available resources, are carefully considered. Analyzing the learning environment – including technology access and delivery methods – is also vital.

Ultimately, the analysis phase provides the critical information needed to make informed decisions throughout the subsequent phases of the ADDIE model, ensuring the instruction is relevant, effective, and aligned with learner needs.

Design Phase of ADDIE

The Design phase of ADDIE builds upon the analysis, translating learning objectives into a structured blueprint. Instructional designers meticulously craft learning strategies, selecting appropriate methods and media to deliver content effectively. This involves outlining the sequence of content, determining assessment strategies, and developing instructional materials.

Key considerations include creating storyboards, writing scripts, and choosing visuals. Learner engagement is paramount, so designers incorporate interactive elements and activities. Accessibility is also crucial, ensuring the design caters to diverse learners.

This phase results in a detailed design document – a comprehensive guide for development. It specifies how the instruction will be delivered, how learners will be assessed, and the overall look and feel of the learning experience, setting the stage for the development phase.

Development Phase of ADDIE

The Development phase of ADDIE brings the design blueprint to life, focusing on creating and assembling the instructional materials. This is where content is produced – writing scripts, recording audio/video, designing graphics, and building interactive elements. Subject matter experts (SMEs) are often involved to ensure accuracy and relevance.

Instructional designers utilize authoring tools and multimedia software to create engaging and effective learning resources. Prototyping is common, allowing for testing and refinement before full-scale production. Accessibility standards are rigorously applied throughout this phase, ensuring inclusivity.

The outcome is a complete set of instructional materials ready for implementation. This includes everything from presentations and videos to quizzes and simulations, all meticulously crafted to support the learning objectives established in the earlier phases.

Implementation Phase of ADDIE

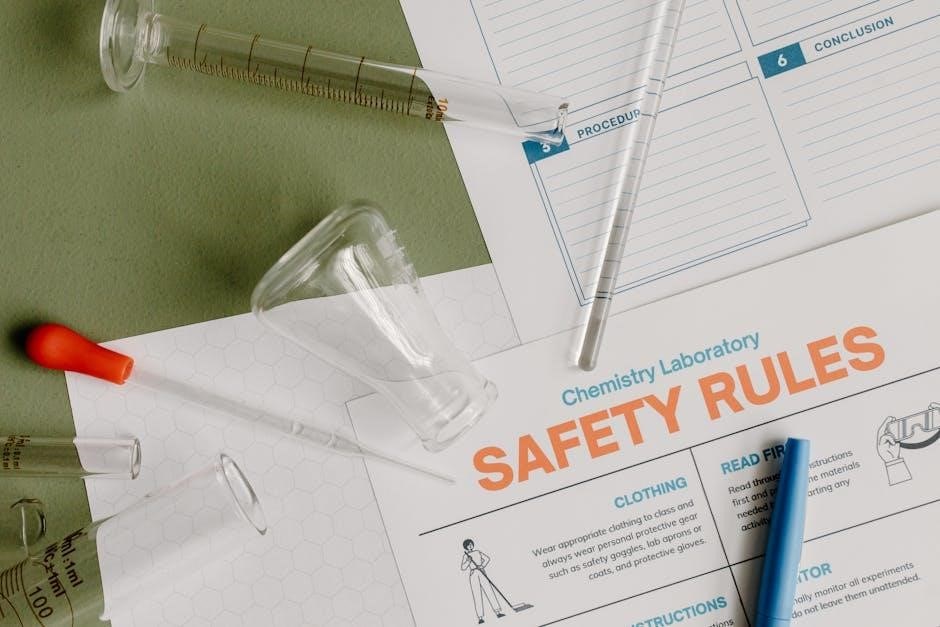

The Implementation phase of ADDIE marks the delivery of the instructional materials to learners. This involves facilitating the learning experience, whether through a traditional classroom setting, online learning platform, or blended approach. Effective implementation requires careful coordination and logistical planning.

Instructional designers often train instructors or facilitators on how to deliver the content effectively. Learner support is crucial during this phase, providing assistance and addressing any challenges that arise. Monitoring learner progress and gathering feedback are also key components.

Successful implementation ensures that learners have access to the resources they need and receive the support necessary to achieve the desired learning outcomes. It’s about putting the carefully designed materials into action and observing their impact on the target audience.

Evaluation Phase of ADDIE

The Evaluation phase of the ADDIE model is a critical, ongoing process, not merely a final step. It involves assessing the effectiveness of the instruction at all stages – formative evaluation during development and summative evaluation post-implementation. Kirkpatrick’s Four Levels of Evaluation often guide this process, examining learner reaction, learning, behavior change, and results;

Formative evaluation provides feedback for improvement throughout the design and development phases. Summative evaluation determines if the instructional goals were met. Data collection methods include surveys, tests, observations, and performance metrics.

Analyzing evaluation data informs future revisions and improvements to the instructional materials. This iterative process ensures continuous enhancement and maximizes the impact of the learning experience, solidifying ADDIE’s position as a foundational model.

Gagné’s Nine Events of Instruction

Gagné’s Nine Events of Instruction offer a systematic approach to designing effective learning experiences. Developed by Robert Gagné, this model outlines a sequence of events intended to facilitate optimal learning and knowledge retention. These events include gaining attention, informing learners of objectives, stimulating recall of prior knowledge, presenting the stimulus, providing learning guidance, eliciting performance, providing feedback, assessing performance, and enhancing retention and transfer.

Each event addresses a specific cognitive process crucial for learning; By following this sequence, instructional designers can create lessons that are not only engaging but also structurally sound, promoting deeper understanding and skill development.

The model’s strength lies in its grounding in cognitive psychology, offering a practical framework for translating learning theory into instructional practice.

Kirkpatrick’s Four Levels of Evaluation

Kirkpatrick’s Four Levels of Evaluation, developed by Donald Kirkpatrick, provides a comprehensive framework for assessing the effectiveness of training programs. This model moves beyond simply measuring participant satisfaction, delving into deeper levels of impact. The four levels are Reaction, Learning, Behavior, and Results.

Reaction measures learner satisfaction with the training. Learning assesses the extent to which learners acquired the intended knowledge or skills. Behavior evaluates the transfer of learning to the job, observing changes in on-the-job performance. Finally, Results measures the ultimate impact of the training on organizational goals, such as increased productivity or reduced costs.

By systematically evaluating at each level, instructional designers gain valuable insights into program effectiveness and areas for improvement, ensuring a strong return on investment.

Cognitive Development Theories and Instructional Design

Instructional designers typically employ models informed by cognitive theories – Piaget, Vygotsky, and Bloom’s Taxonomy – to tailor learning experiences to developmental stages and objectives.

Piaget’s Theory of Cognitive Development & Stages

Jean Piaget’s theory profoundly impacts instructional design, emphasizing that learners construct knowledge actively through experiences. His stages – sensorimotor, preoperational, concrete operational, and formal operational – dictate how information should be presented.

For sensorimotor learners (0-2 years), hands-on activities are crucial. Preoperational thinkers (2-7 years) benefit from concrete examples and visual aids, as they struggle with abstract concepts. Concrete operational students (7-11 years) can grasp logical reasoning with tangible problems.

Finally, formal operational adolescents (12+ years) thrive on abstract thought and hypothetical scenarios. Instructional designers leverage these stages by aligning content complexity with learner capabilities. Activities should promote exploration, discovery, and schema building, fostering cognitive growth. Understanding these stages allows for the creation of age-appropriate and effective learning materials, ensuring optimal knowledge construction.

Vygotsky’s Sociocultural Theory & Zone of Proximal Development

Lev Vygotsky’s sociocultural theory highlights the crucial role of social interaction and cultural context in learning. Central to his work is the Zone of Proximal Development (ZPD), the gap between what a learner can do independently and what they can achieve with guidance.

Instructional designers utilize the ZPD by providing scaffolding – temporary support structures tailored to individual learner needs. This support can take many forms, including hints, prompts, or collaborative activities. The goal is to enable learners to accomplish tasks slightly beyond their current capabilities.

Effective instruction, therefore, isn’t simply delivering content, but facilitating meaningful interactions and providing appropriate scaffolding. Collaborative learning, peer tutoring, and expert guidance are all strategies rooted in Vygotsky’s theory, fostering cognitive development and maximizing learning potential within the ZPD;

Bloom’s Taxonomy and Learning Objectives

Bloom’s Taxonomy provides a hierarchical framework for categorizing educational learning objectives. Ranging from lower-order thinking skills like remembering and understanding to higher-order skills such as applying, analyzing, evaluating, and creating, it guides instructional design.

Instructional designers leverage Bloom’s Taxonomy to craft learning objectives that are specific, measurable, achievable, relevant, and time-bound (SMART). Starting with ‘remembering’ builds a foundation, while progressively challenging learners with higher-order tasks promotes deeper comprehension.

Using action verbs – like ‘choose,’ ‘list,’ ‘evaluate,’ or ‘design’ – clearly defines expected learner outcomes. Aligning assessments with these objectives ensures valid evaluation of learning. Persaud (2018) emphasizes ‘remembering’ as foundational, enabling subsequent, more complex learning. This systematic approach ensures well-structured and effective instructional materials.

Applying Models in Practice

Instructional designers typically employ models by selecting the most appropriate one, adapting it to the specific context, and continuously evaluating its effectiveness for optimal results.

Selecting the Appropriate Model

Choosing the right instructional design model is crucial for successful learning outcomes. Instructional designers don’t simply pick a model at random; the selection process is deeply rooted in a careful analysis of several key factors. These include the learning objectives, the characteristics of the learners, the available resources, and the overall context of the instruction.

For instance, if the goal is to deliver basic skills training with clear, measurable outcomes, the ADDIE model’s structured approach might be ideal. However, if the focus is on fostering critical thinking and problem-solving skills, a constructivist approach, potentially informed by Gagné’s Nine Events, could be more effective. Kirkpatrick’s model then becomes vital for evaluating the impact of the chosen design.

Furthermore, designers often blend elements from different models to create a hybrid approach tailored to the unique needs of the project. There isn’t a “one-size-fits-all” solution; the best model is the one that best supports the learning goals and learner characteristics.

Adapting Models to Specific Contexts

While established instructional design models like ADDIE provide a solid framework, effective instructional designers rarely apply them rigidly. True expertise lies in adapting these models to the specific nuances of each learning context. This often involves modifying phases, incorporating elements from other models, or even creating entirely new approaches.

For example, a corporate training program might prioritize rapid development and implementation, leading to a streamlined ADDIE process. Conversely, a higher education course might emphasize learner-centered activities, drawing heavily from constructivist principles and Vygotsky’s Zone of Proximal Development.

Contextual factors such as budget constraints, technological limitations, and the learners’ prior knowledge also necessitate adaptation. Designers must be flexible and resourceful, constantly evaluating and refining their approach to ensure optimal learning experiences. The key is to view models as guidelines, not rigid rules, and to prioritize the needs of the learners above all else.

The Future of Instructional Design Models

The future of instructional design models is poised for significant evolution, driven by technological advancements and a deeper understanding of learning sciences. While foundational models like ADDIE will likely remain relevant, we can anticipate a shift towards more agile, iterative, and data-driven approaches.

Artificial intelligence (AI) and machine learning are expected to play a crucial role, personalizing learning pathways and automating aspects of the design process. Microlearning, gamification, and immersive technologies like virtual and augmented reality will demand new model adaptations.

Furthermore, a growing emphasis on accessibility, inclusivity, and lifelong learning will necessitate models that prioritize diverse learner needs. The focus will move beyond simply delivering content to fostering critical thinking, problem-solving, and adaptability. Instructional designers will increasingly become learning experience architects, blending established principles with emerging technologies to create truly transformative learning journeys.